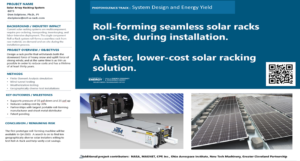

Reduce solar-panel racking and installation costs by 33%

for accessible and affordable solar power

About Roll-A-Rack

Roll-A-Rack is a new solar-panel racking system that reduces racking and installation costs of traditional systems by 30 percent. The material costs are 50 percent less than current racking systems. Installation time and labor costs are reduced by 65 percent.

Designed for flat roofs and ground applications, Roll-A-Rack uses roll-forming equipment to produce on-site, ballasted racking. The single-component Roll-A-Rack is significantly simpler than today’s multicomponent racking systems, which require pre-ordering, shipping, inventory and assembly.

Roll-a-Rack is being developed by a team of scientists, engineers and solar installers with the help of a Small Business Innovation Grant from the U.S. Department of Energy Solar Energy Technologies Office. The effort harnesses a wide range of community resources and Cleveland’s rich engineering and manufacturing expertise, which is represented by the following:

- NASA’s Glenn Research Center is advising on wind uplift forces.

- Ohio Aerospace Institute is supporting product commercialization.

- BT Solar, a local solar installation company, will provide technical assistance and end-user feedback.

- MAGNET, a nonprofit manufacturing consultancy, is validating the mechanical design and advising on strategic business development.

- SDLE Research Center at Case Western Reserve University will perform accelerated weather testing.

- The New Tech Machinery division of Mazzella Companies will build the roll-forming machines, and Sheffield Metals International, also a division of Mazzella, will provide raw materials.

Roll-A-Rack will be available by the end of 2020 .

For Installers

Become a Beta Tester

First 100 kW of racking are free

Roll-A-Rack is seeking developers and installers for beta testing

Benefits

- Early access to cost-saving technology with minimal risk

- First 100 kW of racking are free

- Racks will be roll formed on the project site by Roll-A-Rack at no cost

- For commercial building projects, racks will be formed and lifted to rooftop at no cost

- Roll-A-Rack will perform wind uplift analysis to determine ballast requirements

- Staff will be trained at no cost

- The test site will become a case study, which can be used for marketing

Requirements

- A ballasted solar project with a minimum size of 100 kW

- Projects must be performed between Nov. 2021 and July 2022

- Testers must allow time-and-motion studies on their installation

For more information email beta@roll-a-rack.com, or call (216) 391-7400

Contact Us

for information and inquiries

Don Scipione

dscipione@roll-a-rack.com

216.346.6955

3821 Prospect

Cleveland, Ohio

Our Team

Advisers

Brandon Cornuke

Vice President, Startup Services

MAGNET

Michael Keller

Senior Product Development Engineer

MAGNET

Alec Simon

Senior Startup Advisor

MAGNET

Anthony Gillespie

Senior Program Manager

Ohio Aerospace Institute

Daniel Gisser, MBA, PhD

Senior Project Manager

Ohio Aerospace Institute

Nicole Stika

Vice President, Energy Services

Greater Cleveland Partnership

Joe Mossbrook

Managing Partner

Acclaim Communications